注释

|

还请张贴您完整的 GRBL 定义。No dia domingo, 27 de agosto de 2017, Daumaz <notifications@github.com> escreveu:

|

|

看起来你正在丢失步骤。您在驱动程序上使用什么微步设置?No dia domingo, 27 de agosto de 2017, Daumaz <notifications@github.com> escreveu:

|

|

我真的不认为它正在丢失步骤,如果我要以错误的方式添加反向绘制的部分路径并说从那里继续它会构成正确的形状。我不使用微步,我的 GRBL 设置: |

|

这是反弹

|

|

起初我也这么认为,但后来我看到它移动了 10 毫米,然后你真的可以听到并看到电机在移动它 |

|

尝试保持电机始终启用以查看 |

|

试过了,没有变化 |

|

你能发布你的 gcode 你用什么来发布代码?No dia domingo, 27 de agosto de 2017, Daumaz <notifications@github.com> escreveu:

|

|

我正在使用画架。慢跑时也会出现这个问题,不要认为代码与它有任何关系。 |

|

更改信号线(移动它们时我无法使问题发生)这里是什么意思?No dia domingo, 27 de agosto de 2017, Daumaz <notifications@github.com> escreveu:

|

|

我移动了步进和方向信号线(从 Arduino 到驱动器)可能使它们失去联系,但 cnc 保持正确的方式 |

|

你能指出发生这种情况的线路吗?您是否尝试过使用其他发件人?No dia domingo, 27 de agosto de 2017, Daumaz <notifications@github.com> escreveu:

|

|

它总是不同的,不,我没有使用任何其他发件人 |

|

只是为了排除发件人,您可以尝试使用不同的代码使用相同的代码,例如 ugcs No dia domingo, 27 de agosto de 2017, Daumaz <notifications@github.com> escreveu:

|

|

我有UGCS,会试试的。 |

|

刚刚通过 UGCS 运行相同的代码,问题仍然存在 |

|

您是否已确认原因不是机械原因? |

|

是的,正如我之前提到的,它有时会跳得更安静一点,然后我可以清楚地听到电机快速反转的声音。我已经设置了电流限制来驱动我的电机。 |

|

更新:我断开了步进器接线屏蔽并提起了金属工作台表面的电缆。现在,只要打开电源,X 轴就会在两个方向上随机跳跃,它也会对我的触摸(在屏蔽层上)做出反应。起初它甚至不需要屏蔽,可能在这里有什么东西…… 更新:最重要的是一个有问题的驱动程序,改变了它,不再随机移动,主要问题仍然存在 |

|

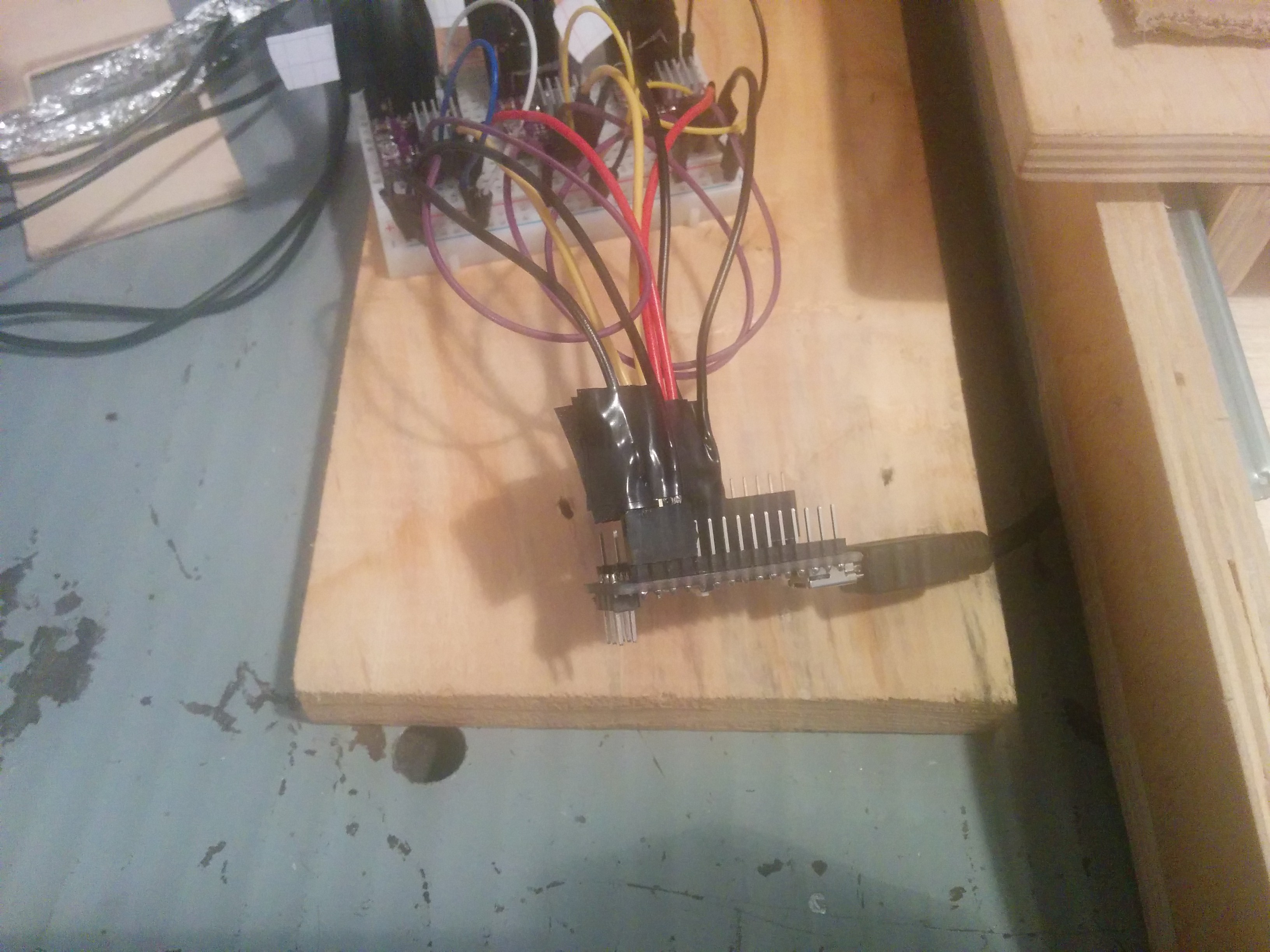

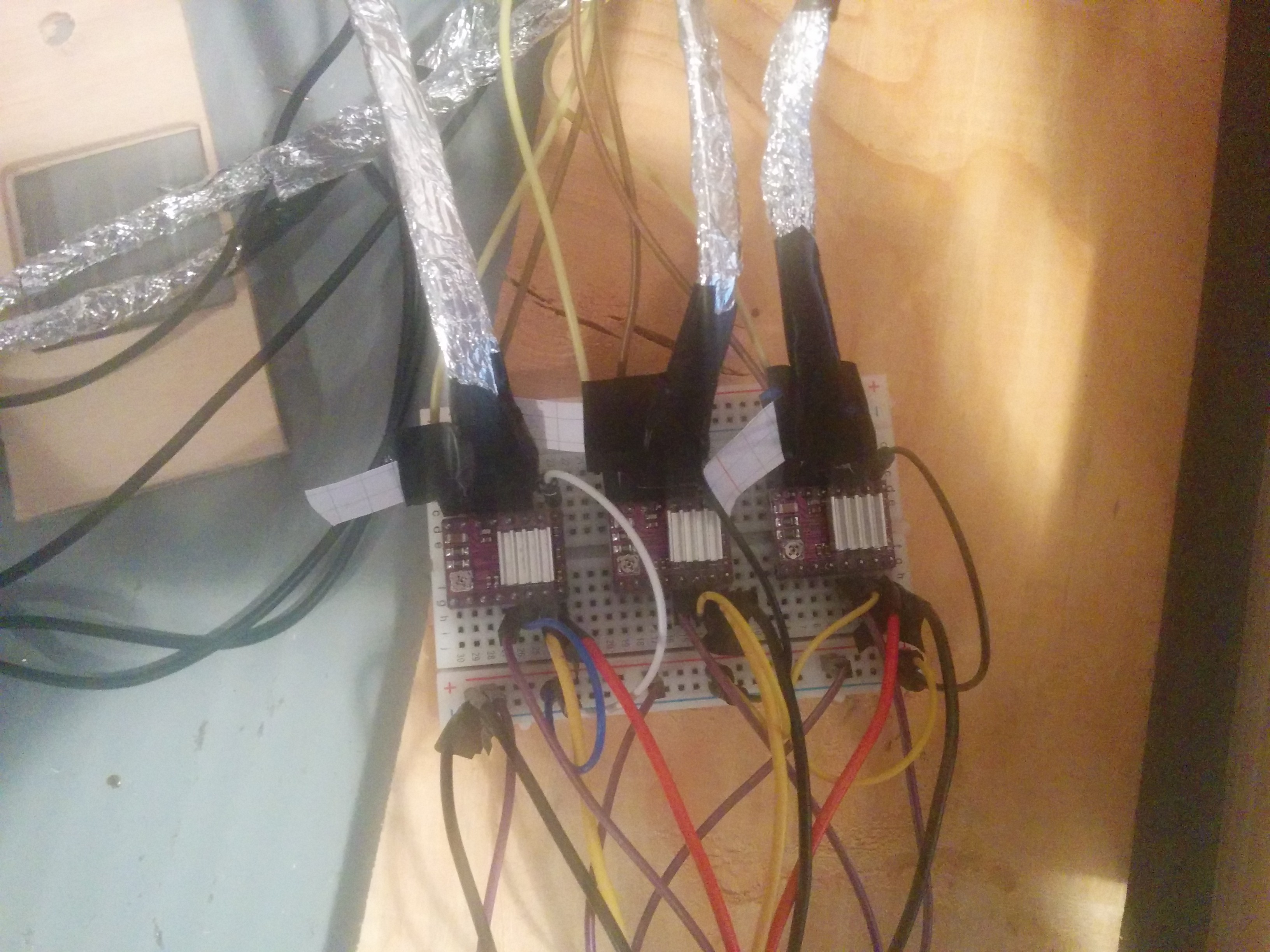

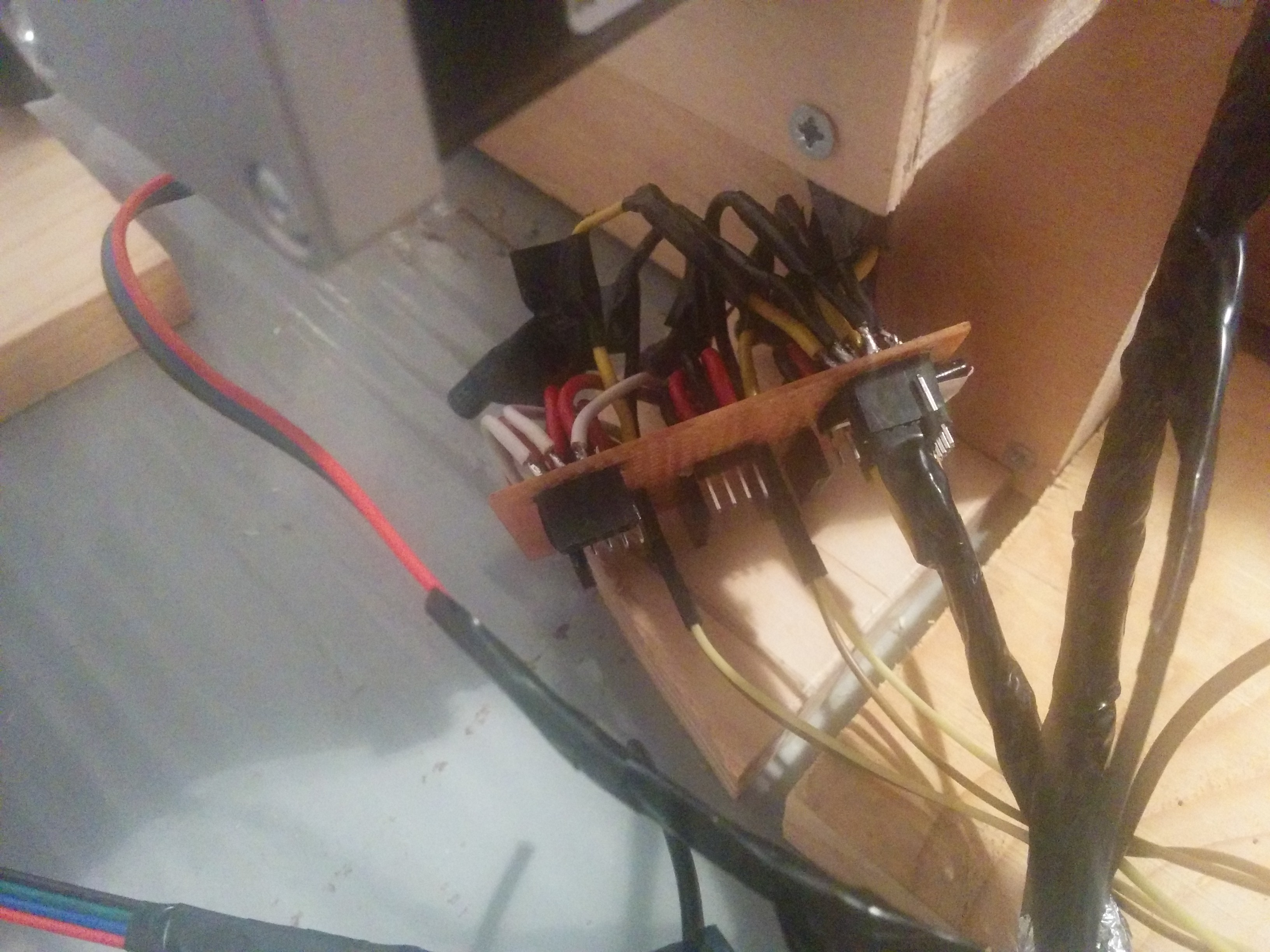

你能给你的电子产品拍几张吗 No dia domingo, 27 de agosto de 2017, Daumaz <notifications@github.com> escreveu:

|

|

您确定所有组件之间都有共同点吗? |

|

图片来了,我已经连接了 Arduino 和所有驱动程序接地 |

|

电器没问题。这看起来和听起来像是对我的强烈反对。检查你的耦合器。打开千分表并来回慢跑几十次,看看它返回哪里 2017 年 8 月 27 日下午 1:29,“Daumaz”<notifications@github.com> 写道:图片来了,我有 Arduino 和所有所有驱动程序接地连接 – 您收到此消息是因为您发表了评论。直接回复此电子邮件,在 GitHub < #1278(评论) > 上查看,或将线程静音 < https://github.com/notifications/unsubscribe-auth/AQlzDHm56o9htIAPE3jgmyYKKNxsTof8ks5scZmAgaJpZM4PDwAX >。

|

|

看起来您正在使用热胶作为耦合器,哈哈。你有什么球果?接线要么有效,要么无效。丝杠与普通螺母有很大的间隙。Openbuilds 出售了一种你应该投资的很好的反冲。

|

|

And the twisted yellow and black wires coming of of spindle power is +12V for brushless motor cooling fan which is now cooling the drivers |

|

This really looks more like lost steps to me and the motors are stalling occasionally. In your video, you state that the loud rattling in your machine is from eBay bearings. I’m not sure if that is really the case, but I would suspect that your machine is prone to binding randomly due to the rattling. This binding is causing your steppers to lose steps. I don’t think this is backlash, because it makes a decent circle pretty consistently. I don’t think it’s something electrical because it would happen much more often than what is in the video. |

|

Those are plywood discs held together by glue and hot glue to give some flex. The screw side has a nut inside and the metal plate for pressing the last disc to the screw. Yeah sketchy :), but works. The whole screw system is temporary, I will get the 8mm diameter 2mm pitch ones with good ball bearings later, just what to see it move correctly. |

|

I had problems with slipping at first chamnit, I have heard the sound it makes. My video did not catch any big ones, but when it moves extra 5mm you can really hear the motors give the extra effort to do so. The only thing about possible slip would be the Z axis while its accelerating, it just does not sound completely right, steps are I would say more violent. That is why I increased the acceleration of the Z axis a lot, for the weight it caries it does not have any issues working even without acceleration (full speed always) |

|

Lost steps isn’t slipping. It’s your motor failing to move. If it’s doing it during a change in direction, it can be instantaneous and hard to hear. Your problem doesn’t have anything to do with the Z-axis, it’s the X and Y during the job. And you should be decreasing acceleration, rather than increasing it ( |

|

jahnj0584 i use 2 regular nuts spaced from one another by plywood plates and sheets of cardboard for final adjustment |

|

I understand that I am making things more difficult for the Z axis and it has nothing to do with the main problem, just thought I mention it. I always thought lost steps and slipping are the same, now i see what you mean, I will try less acceleration then. |

|

I meant less acceleration for Z. If you are experiencing lost steps at 10mm/s^2 already, reducing it further won’t really help that much. I would really concentrate on reducing friction and binding on your machine. If you think it’s something else, you can detach your steppers from your machine and come up with a way to check if any of your steppers are going the wrong direction. Anyhow, this issue is closed, since this isn’t a problem with Grbl itself. |

|

从电子学角度的两个建议

|

大家好,我正在尝试构建我的第一台数控机床,但我正面临这个问题。我的 GRBL 控制的 cnc 有时无法及时为下一组步骤更改步进器方向,因此它开始以错误的方式移动,然后快速切换到正确的方式,不时再次抵消整个操作。我注意到它很难在左右(X 轴)和前后(Y 轴)之间切换。我没有太多关于 Z 轴的信息,因为它移动不多而且更难观察(没有让机器撞到工件或无意中向上移动,这可能没问题)。X 和 Y 轴由相同的 Nema 17 0.6Nm 1.5A 电机驱动,Z 轴使用 Nema 17 0.45Nm 1.7A。我使用在 24V pc 电源上运行的 DRV8825 步进驱动器。故障发生在更困难的路径上(画架基本形状没有任何问题)并且在慢跑时,在 cnc 以错误的方式移动时它似乎走得更快一些。这是其中一个操作的视频:https://www.youtube.com/watch?v=cRGsGR6I628&feature=youtu.be

我尝试过的事情:

降低进给率

屏蔽高电流电缆

将驱动器移回面包板(我使用的是自制电路板)

反转方向引脚

反转步进引脚

增加步进空闲延迟($1)或进给率可能会减少偏移量,进一步增加这个值没有效果

发送+ 5V到所有endswitch引脚

为Arduino使用外部电源

在方向引脚上添加下拉电阻

减少X和Y的步长/毫米(解决了我遇到的不同问题)

使用不同的Arduino板

更改信号线(移动它们时我无法使问题发生)

我没有想法,在谷歌上找不到更多的东西,可能没有提到我试过的所有东西。有人有想法吗?帮助将不胜感激。